Product Lines

Created by Wolverine

Since our establishment, we’ve made a point to design and manufacture our own product lines. Wolverine is proud to offer converter dollies, tire recycling equipment, and landfill systems.

Converter Dollies

- Air ride or spring ride

- Fixed or floating hitches

- Tandem or single axle

All our converter dollies are DOT certified with full fenders and lighting when completed. They can be custom-built to order!

CONTACT US about our converter dollies’ features and price points.

Tire Recycling Equipment

Put a Wolverine debeader at the front of your process line and gain the many benefits of early wire removal.

Truck Tire Debeader

The unit removes each of the two beads simultaneously and pulls them through hardened steel die plats to strip most of the surrounding rubber.

Read More

The entire unit is controlled by a PLC (programmable logic controller) and powered by an electro-hydraulic motor-pump set. The electrical system is NEMA 4 rated and further protected for wash-down or outside operation. Rain water in the tires is not a problem. Each unit is designed and built like a battleship to provide decades of dependable service. All wear parts are in stock at Wolverine and may easily be replaced on the machine.

[Standard Truck Tire Debeader Information, Heavy Truck Tire Debeader Information, and Heavy Truck Tire Debeader Specifications documents are not accessible.]

CONTACT US for more information about our truck tire debeaders.

Passenger & Light Truck Tire Debeader

Load tires on the feed conveyer with the same workers normally required to supply the shredder. The crew may place tires side-by-side or spaced out. Different sized auto and light truck tires (145R12 to 265/75R16 and most 17’s) may be loaded interchangeably. The cyclic rate when fully supplied is 500 tires per hour.

The unit removes two beads simultaneously and pulls them through hardened steel die plates to strip most of the surrounding rubber. The tire is then counted as it’s discharged onto the shredder feed conveyer. The bead wires drop onto a belt conveyer for removal from either side.

Read More

CONTACT US for more information about our passenger and light truck tire debeaders.

Rubber Mixer

CONTACT US for more information about our rubber mixer.

Rubber Fine Grinder

The fine grinder is primarily used for grinding 3/8” to 1/2” rubber chips into 10-40 mesh rubber pieces. This is the size required to make rubber moulded products.

CONTACT US for more information about our rubber fine grinder.

Shaker Table

Shaker tables are designed to separate the size of mesh needed for your product (10, 20, 30, 40 Mesh). They also remove the fluff left over from the tires, which stays on top of the screens.

CONTACT US for more information about our shaker table.

Conveyors

All our conveyors are custom-built to fit whatever system you’re using.

CONTACT US for more information about our rubber mixer.

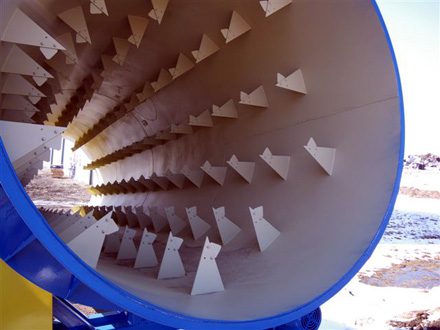

Custom Landfill Systems

These images have been provided by Louise Waste Management of the R.M. of Louise. The process of their Wolverine system is as follows:

- Bags loaded into the bag ripper

- Items are sorted to determine what’s garbage and what’s recyclable

- Garbage goes down a conveyor to the drum magnet, where the metal contents are removed

- Garbage then goes back onto another conveyor, which takes it to the shredder, where everything is shredded

- Once shredded, the garbage is ready for disposal

CONTACT US for more information our custom landfill systems.